The basis for this is the device description for the instrument, which is read into the controller and the systems for engineering, configuration, alarm collection, and asset management. This makes any information from the field device uniquely identifiable. Additionally, device profiles define manufacturer- and product-independent access to standard variables, which simplifies engineering and installation.

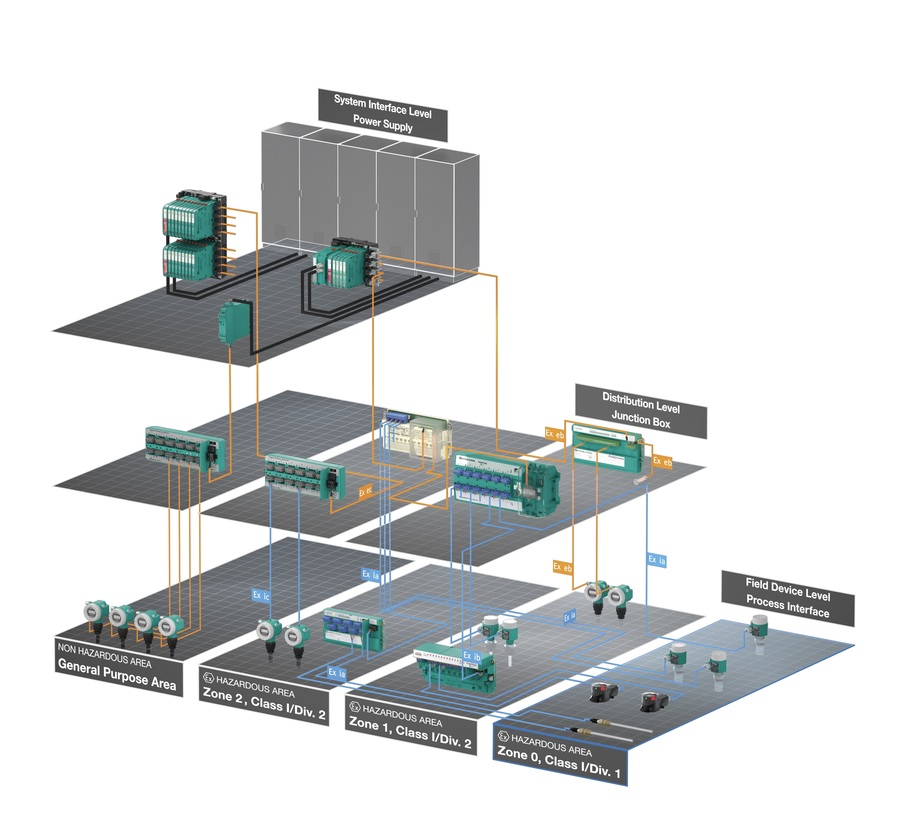

Structure and Topology

A segment consits of a power supply, one or more field distributors, and the instruments connected to them.

System Interface/Power Supply

The power supplies for FOUNDATION Fieldbus H1 and Segment Couplers for PROFIBUS PA are installed in the control room. The power supply provides the segments with up to 31 V DC, 500 mA. It is compact or modular with optional redundancy. The integrated impedance matching circuit enables field communication transmitted as a trapezoidal AC signal, which the station supply would otherwise be short circuit.

Field Distribution

The Segment Protector or FieldBarrier are installed in enclosures in the field. They form the link between the power supply and the field device. Intelligent error protection at the spur protects the segment when working on an instrument. For example, the segment is protected against short circuits, contact bounce, and incorrect field device communication behavior (Jabber).

Process Interfaces/Field Devices

The multi-input/output and the temperature multi-input device are used as data collectors for the connection of simple and intrinsically safe signals. They connect up to 12 discrete or 8 analog signals to the control system via a single fieldbus address and offer special features such as breakaway and runtime monitoring of valves.

+49 621 776-0

+49 621 776-0